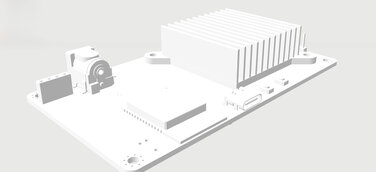

After extensive comparative tests, temperature measurements, and material analyses, the development team made a conscious decision to take the next step and set an example: All NerdQX series devices are shipped with a copper-anodized VREG cooler.

This decision was not a marketing ploy, but a question of standards. Copper conducts heat much more efficiently than aluminum, enabling lower operating temperatures with the same noise level. The anodized surface also provides corrosion protection, improved heat distribution, and a distinctive, high-quality look. Compared to the aluminum version, temperature improvements of 5 to 10 °C were measured – with more stable voltage and lower overall power consumption.

Pure solid copper variants showed hardly any measurable advantages in the tests, but were significantly more expensive. The copper-anodized cooler thus proved to be the perfect balance between efficiency, stability, and economy.

The result is a real game changer: no more worries about overheated VREGs. Even under high load or overclocking, the area remains within the optimal temperature range, so the board runs more stably, the ASICs are more consistent, and efficiency increases noticeably.

The advantages are measurable and immediate:

- Significantly lower power consumption due to reduced heat loss.

- Cooler circuit board, more stable ASIC performance.

- OC-ready ex works, no additional cooling required.

- Longer service life and higher operational reliability.

Whether passive or active, the new VREG cooler in the NerdQX is a unique selling point in the field of open hardware home mining. The decision to go with the copper-anodized version instead of the aluminum one was a conscious one by the team-driven by the desire to deliver a perfect product, not just a functional one.

The NerdQX thus proves that open-source hardware can not only keep up with industrial standards, but even surpass them in some areas.